MODEL TEST: FRANCIS TURBINE

In order to further expand the reputation that has been built up over the years as an excellent turbine manufacturer with best efficiency, we at WWS Wasserkraft rely on constant development and research to further optimize existing processes. Therefore, this time our Francis turbines were put to the test:

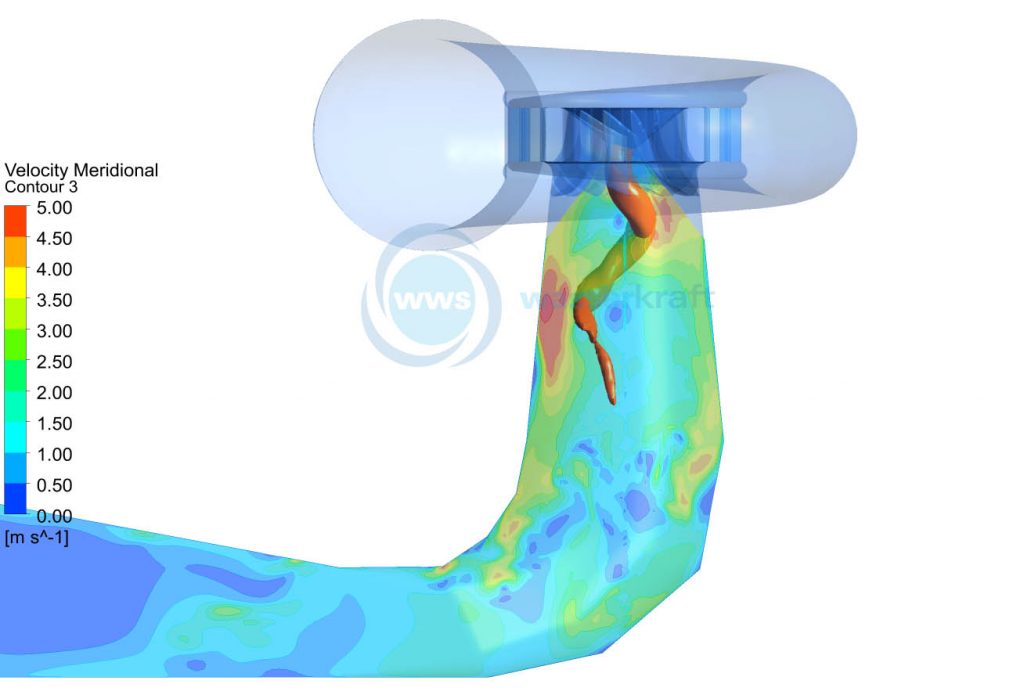

The turbine hydraulics for Francis turbines developed at WWS are used for specific speeds from 20rpm to just over 100rpm. The recent model test was carried out to obtain a comparison to the calculated results in the CFD simulations. To receive additional information for refurbishment projects, we chose a suitable model scale to also test an existing old runner from the year 1980. This runner was installed in the model turbine and tested on the turbine test bench in compliance with all common IEC standards. Therefore, after all measurements were completed, a comparison could be made between the old runner design which is not state of the art and a new, nowadays used runner geometry.

Since the behavior of the system in extraordinary operational cases like an emergency shutdown is of great interest to the plant operator, this was also analyzed in the course of the water hammer calculation.

After completing all tests, a more than satisfactory conclusion could be drawn about the WWS turbine hydraulics. The calculated efficiency level matched exactly with the measurements. The same results showed up looking into the real cavitation behavior of the runner compared to the calculated values.