The American engineer James B. Francis developed the Francis turbine named after him in 1849. In 1913 the Austrian Professor Viktor Kaplan developed on the basis of the Francis turbine the Kaplan-Turbine.

WWS FRANCIS-TURBINE

SOLID & DURABLE

The history of the Francis turbine

Application area of the Francis turbines

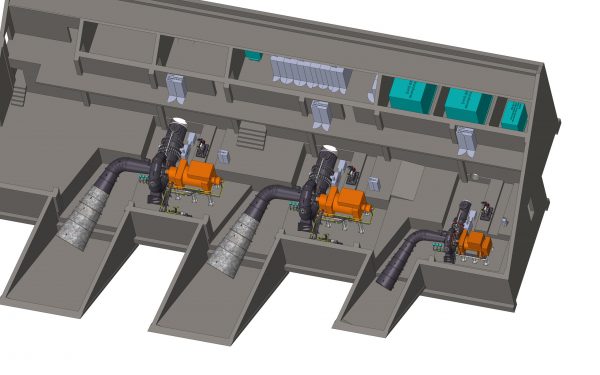

Francis turbines are ideal for medium head (10-200m) and medium flow rates. They can be used in both run-of-river and storage power plants and are the most common type of turbine.

Depending on your individual requirements, WWS has the best suitable solution

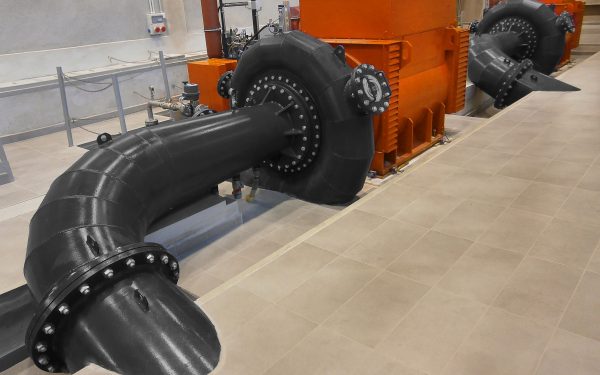

- Horizontal Francis turbine

- Vertical Francis turbine

Thanks to the ongoing development of the Francis Turbine, an efficiency of up to 95% can be achieved. Furthermore, through direct coupling with the generator, additional bearing losses are avoided and the overall efficiency is increased.

„All from a single source ”- True to our company slogan, we also supply the necessary accessories for your turbine. This includes hydraulic steel structures, control systems and much more.

Operating principle of the Francis-Turbine

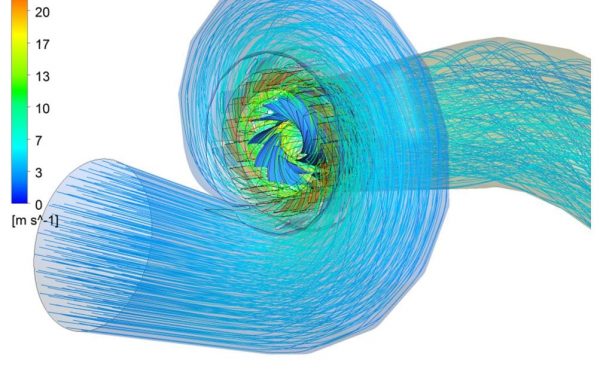

At the Francis turbine the water is directed through the spiral-shaped steel housing to the fixed guide vanes of the spiral onwards to the adjustable guide vanes (distributor) and further on to the francis runner. The adjustable guide vanes allow to regulate the amount of water flowing in into the turbine. The water is deflected in the runner 90 degresse. The energy released in this way sets the francis runner and the usually directly coupled generator in a rotary motion. Since the water pressure at the runner inlet is not the same as the water pressure at the runner outlet, the Francis turbine is referred to as an overpressure turbine.

Further development of the Francis turbine by WWS Wasserkraft

Since Francis turbines cover a very wide range of heads, continuous development is also required here, both in the materials used and in the hydraulic properties of the turbines.

At WWS, a wide range of specific speeds (Nq) are used, which are calculated using the latest state CFD simulations. The design bases for this are the calculations according to Thomann and Siervo.

The resulting runner geometries are carried out in the proven X-Blade design in order to achieve maximum efficiency and the best anti-cavitation properties.