The Austrian engineer Viktor Kaplan revolutionized energy generation in 1913 with the further development of the Francis turbine. Since then, this turbine is named Kaplan turbine.

WWS KAPLAN TURBINE

THE FLEXIBLE ONE

The history of the Kaplan turbine

Application area of Kaplan turbines

These turbines are ideal for utilization with low head (up to 40m) and large amounts of water. Kaplan turbines are mainly used as run-of-river hydropower plants.

Depending on your individual requirements, WWS offers the most suitable solution.

- Kaplan open-flume turbine and concrete spiral

- Kaplan spiral turbine horizontal or vertical

- Kaplan bulb or pit turbine

- Kaplan S Turbine

Our Kaplan turbines are equipped with 3 to 6 blades depending on the type and head and have efficiencies of up to 93%.

If possible, a direct coupling of the generator and the Kaplan turbine is preferable. Otherwise, power transmission can be realized by using flat belts or gearboxes, depending on the performance class and installation situation.

“All from a single source” – True to our company slogan, we also supply the necessary accessories for your turbine. This includes hydraulic steel structures, control systems, and much more.

Operating principle of the Kaplan turbine

The Kaplan turbine was developed by the Austrian professor Viktor Kaplan based on the Francis turbine. The Kaplan turbine is also referred to as an overpressure turbine because the water pressure decreases continuously from the entry into the runner to the exit. Both the blades of the runner (similar to a propeller) and the guide vanes of the turbine are adjustable.

The guide vanes ensure that the water hits the runner blades at an optimal angle and transfers the energy optimally. This double regulation makes optimal use of the available water and always achieves the best possible efficiency.

Optimization of the Kaplan turbine by WWS Wasserkraft

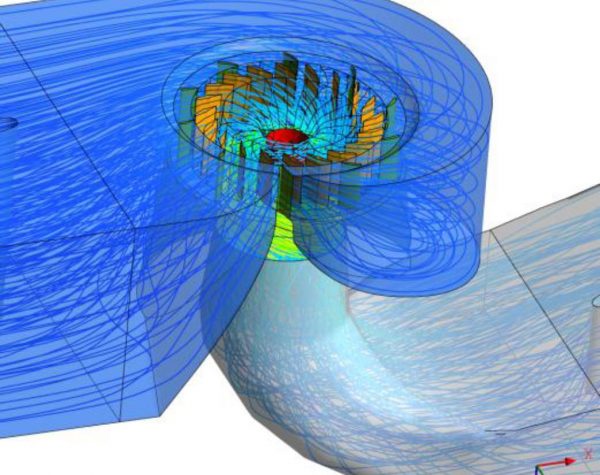

The Kaplan turbine has been generating renewable energy for more than 100 years, but there are always opportunities for optimization. State-of-the-art CFD simulations and the use of three-dimensional computer networks allow project-specific adjustments to the blade geometry and improvements to the suction height.

Based on this CFD calculation, WWS has developed many different geometries for Kaplan runner blades and the associated spiral housing and draft tube properties to cover all customer-specific areas of application.